Reducing Our Water Footprints Through Loop Reticulation

Recognizing the increasing scarcity of water in Sub-Saharan Africa due to climate change, the manufacturing plant prioritizes water-wise practices as a cornerstone of its green manufacturing initiatives.

During the wet processing stage of textile production, the manufacturing plant has implemented a closed-loop water reticulation system.

This innovative system allows for the reuse of 30-40% of the process water.

This significantly reduces overall water consumption and, even more importantly, minimizes the amount of wastewater generated.

By reusing water, the manufacturing plant:

✧ Conserves this vital resource for future generations.

✧ Reduces the environmental impact of textile manufacturing.

✧ Water-wise practices

✧ Closed-loop water system

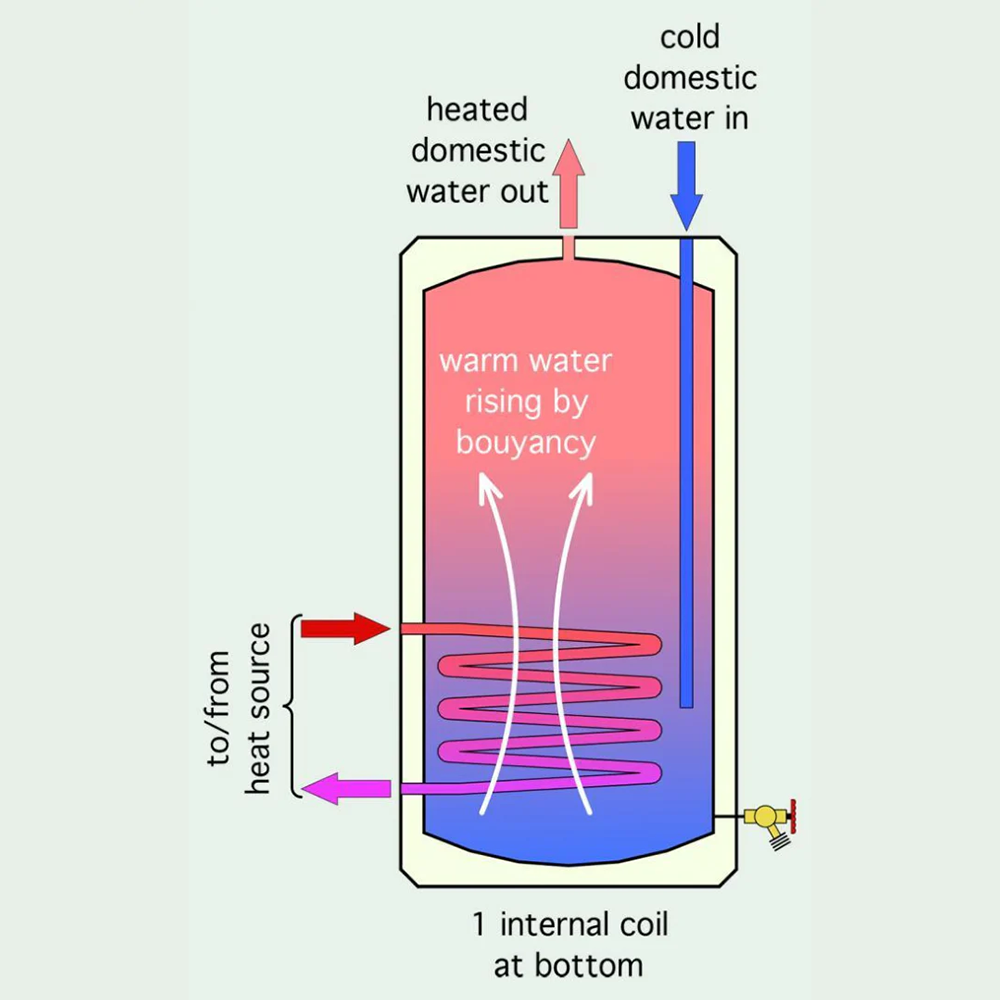

Energy-Efficient Heating with Heat Recovery

The processing and manufacture of technical textiles generate significant amounts of waste heat.Traditionally, this heat would be expelled into the atmosphere, contributing to energy waste and environmental warming.The manufacturing plant has implemented a closed-loop heat exchanger system to address this challenge.This innovative system captures waste heat from the hot air and transfers it to water needed for other manufacturing processes.

The heat exchanger effectively raises water temperature from room temperature to 60°C, significantly reducing the energy required for heating elsewhere in the plant.

By recovering waste heat, the manufacturing plant:

✧ Minimizes its environmental impact by lowering greenhouse gas emissions.

✧ Promotes energy efficiency within the production processes.

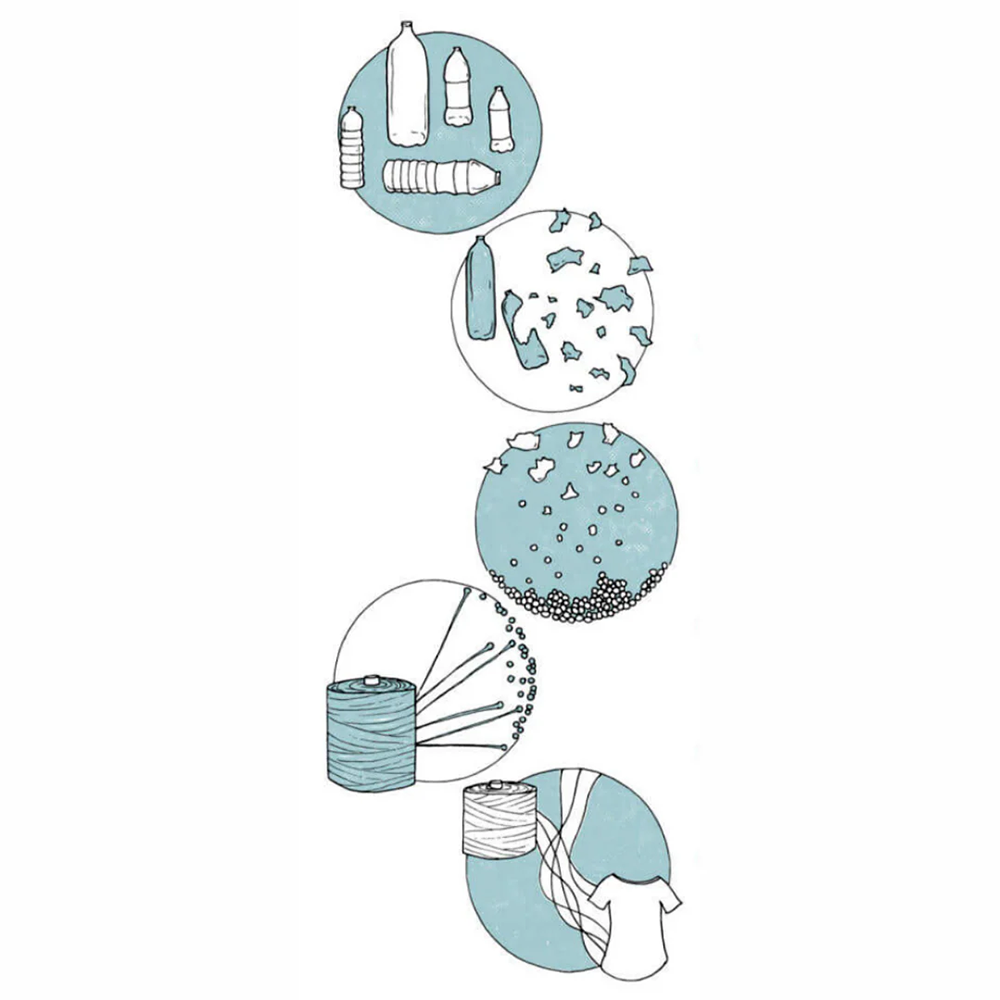

Minimizing Waste Through Repurposing and Recycling

The weaving process inevitably generates polyester offcuts and waste. Traditionally, this waste would be landfilled. The manufacturing plant, however, has taken aproactive approach by partnering with various organizations specializing in waste repurposing and recycling.

✧ Recycling into New Fibers: A significant portion of the polyester waste is recycled back into fibers. This recycled material is then processed into non-woven fabrics, reducing reliance on virgin polyester.

✧ Creative Upcycling Initiatives: The manufacturing plant also collaborates with creative partners who repurpose waste into valuable products. Examples include school bags, beds for the homeless, and hand-woven rugs.

✧ Local Repurposing: All remaining offcuts are repurposed by local vendors who transform them into various products like bags and even traditional artwork. This not only minimizes landfill waste but also empowers local businesses.

Prioritizing Sustainable Materials

The textile industry has a history of using some harmful raw materials. The manufacturing plant recognizes this and takes a critical approach to material selection. Every raw material is evaluated for its environmental and human health impact. The plant prioritizes selecting the most environmentally friendly options while ensuring product efficacy remains uncompromised.

Here are some examples of the plant's success in sustainable material selection:

✧ Elimination of Chlorinated Materials: The plant has successfully removed chlorinated raw materials from its acrylic coatings.

✧ Greener Surfactants: They have replaced harmful APEOs (alkylphenol ethoxylates) with more eco-friendly surfactants.

✧ Safer Fluorocarbon Technology: A shift has been made towards safer C6 fluorocarbon technology, ultimately aiming for complete replacement with fluoro-free dendritic polymers.

Conclusion

In light of the comprehensive analysis we've shared, it becomes evident that the decision between polyester and natural fiber canvases is not just about comparing immediate benefits but involves a deeper understanding of their environmental implications over time.

At ACF, we are committed to embracing practices that not only foster the sustainability of our planet but also ensure the enduring legacy of the art created on our canvases.

We understand that the art world's shift towards more eco-friendly materials is a nuanced journey, involving considerations of water use, energy consumption, emissions, and the lifecycle of products.